|

A quickie explanation on how to make a bead |

|

|

What I use to make glass beads................... Torch |

|

|

|

|

|

Start heating up the kiln in which you will anneal beads. Beads are annealed to relieve the internal stress created when glass is taken from a solid to a semi-solid. The constant temperature should be very near 960° Farenheight. |

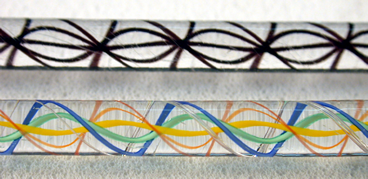

| A torch using an oxygen-propane mixture is used to melt the glass to form the beads. The torch I use is a Minor Bench Burner. While your kiln is heating it's a good time to pull stringers - spaghetti thin sticks of glass - and twisties and latticino - several colors of glass twisted together. These will be used later to decorate your beads. | |

|

|

|

You are now ready to make a bead. Pick up a mandrel that has previously been coated with bead release (so the glass will not stick to them) in one hand. In the other hand a rod of glass. Slowly introduce the glass rod into the flame. If the rod gets too hot too quick, it will thermal shock and send pieces of hot glass everywere. When the glass is hot and starting to move, wind on a preheated mandrel. Touch the glass lightly to the bead release while turning the mandrel to smoothly apply the glass and start forming the bead. When you have applied the amount of glass you want, use gravity to round out the bead. At this point you can use twisties, latticino, various metals, enamels, etc. to decorate the bead. When the bead is 'finished' it is placed into the kiln |

|

|

|

|

After the kiln reaches room temperature the beads may be removed from the kiln and soaked in water to help soften the bead release and make the beads slip off the mandrels. To complete the process and make the beads ready to design with, you must remove the residual bead release from the hole in the bead. I use a diamond bit bead reamer for this. |

|